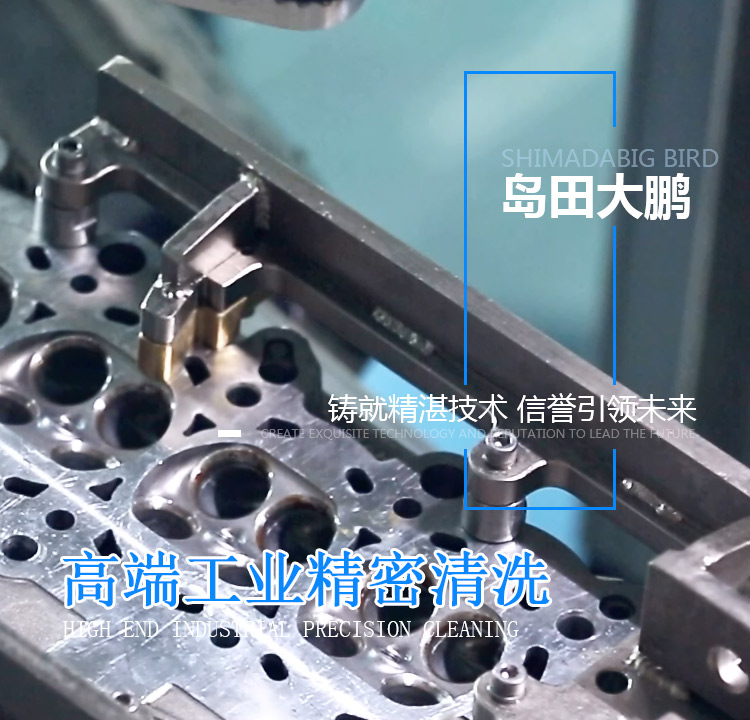

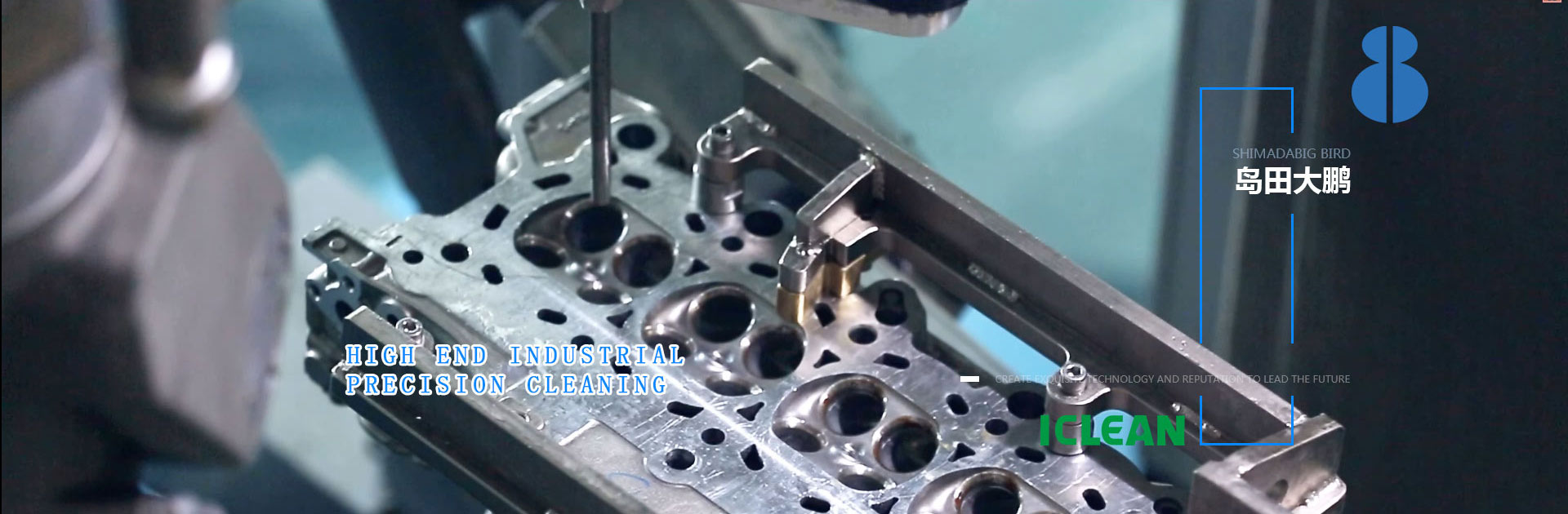

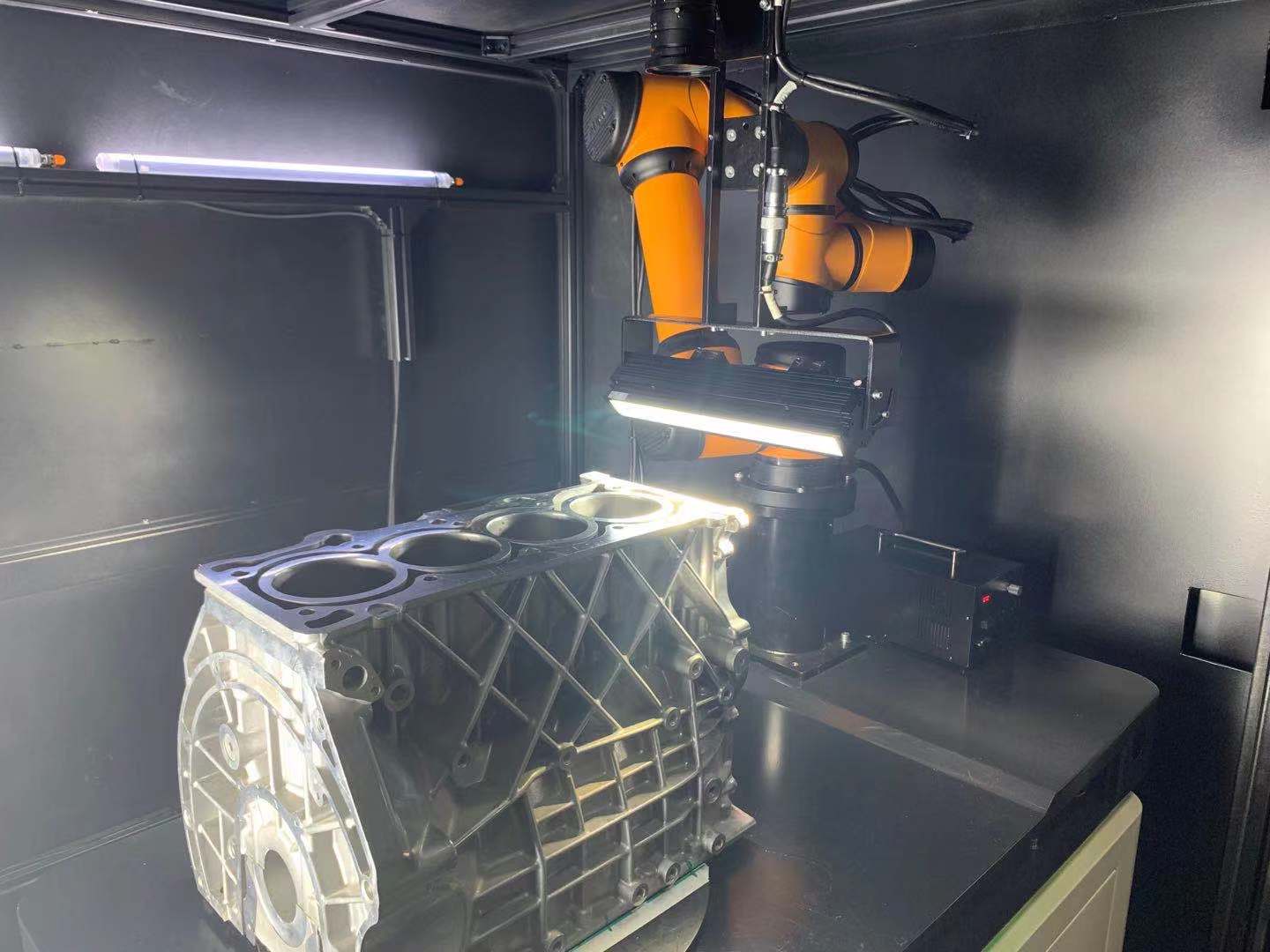

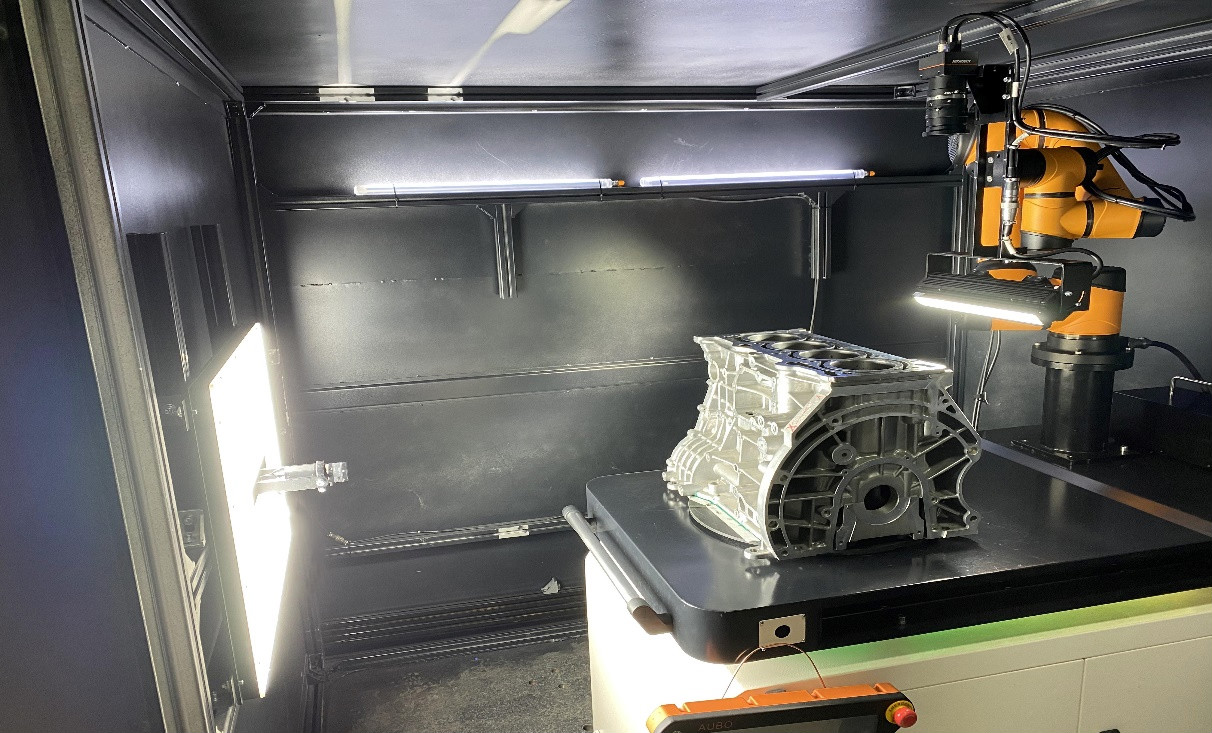

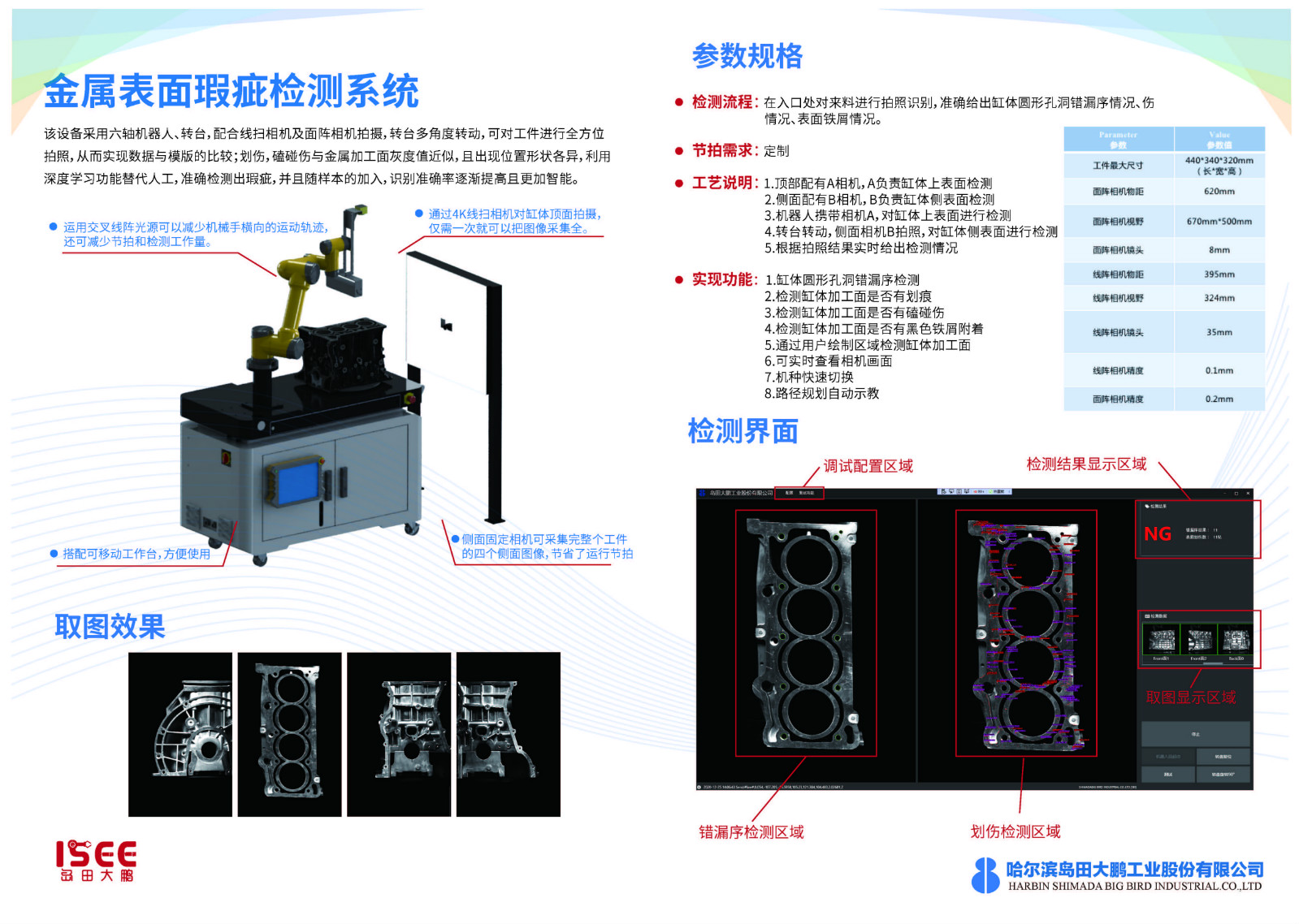

Surface defect detection equipment

It is used to test whether the workpiece is qualified. The test items include hole position, hole size, wrong or missing sequence, workpiece scratch and bump.

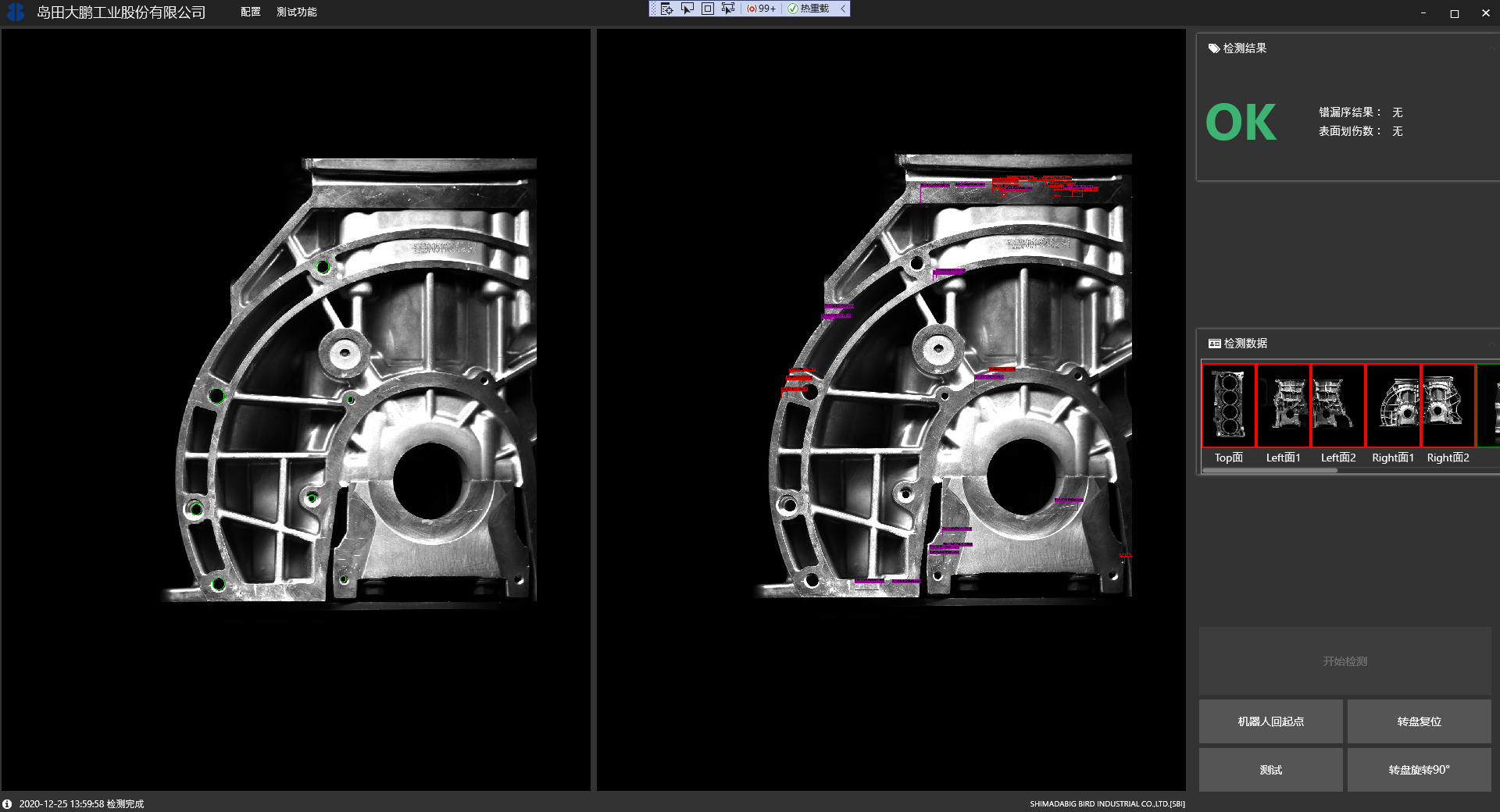

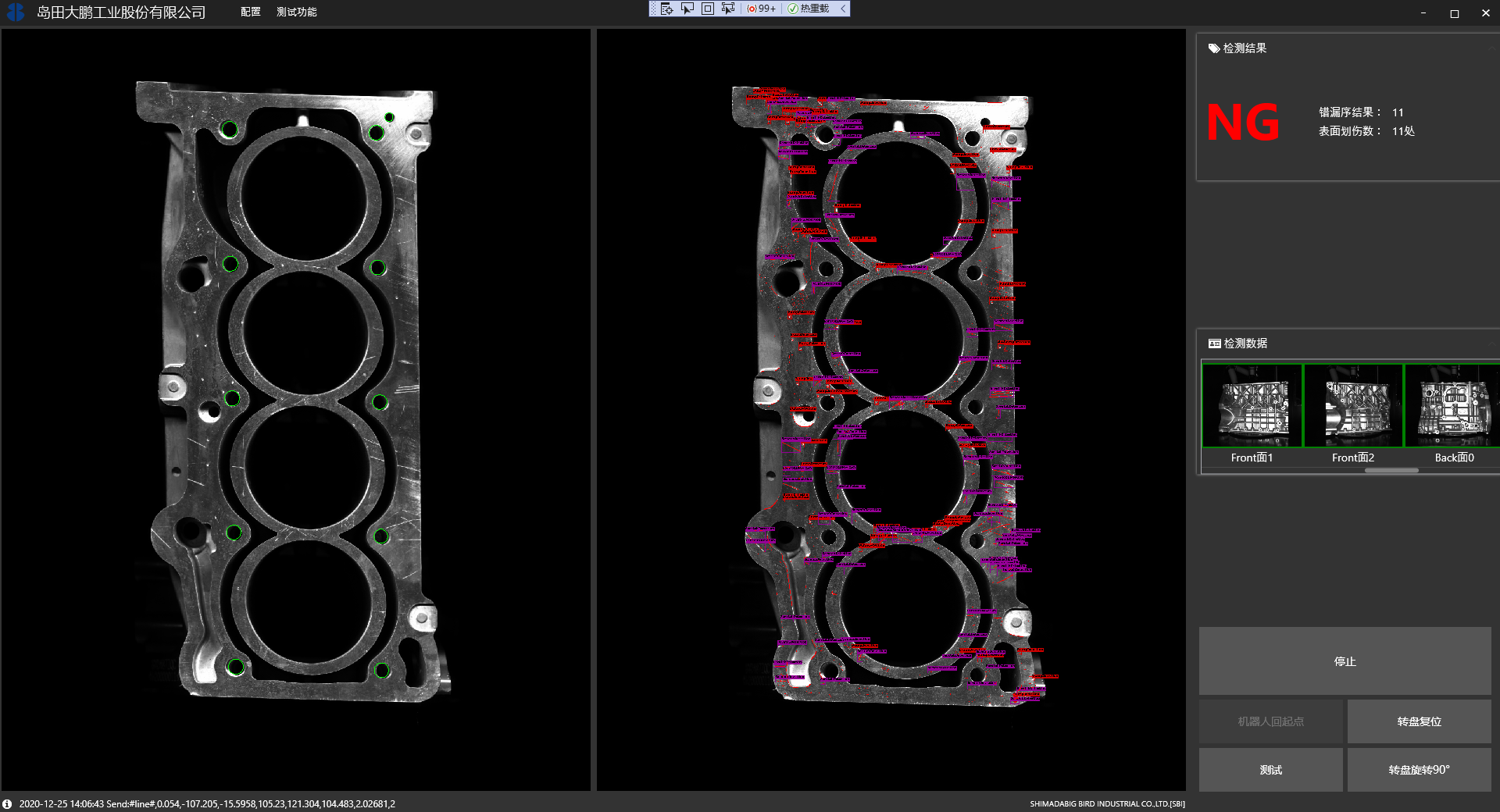

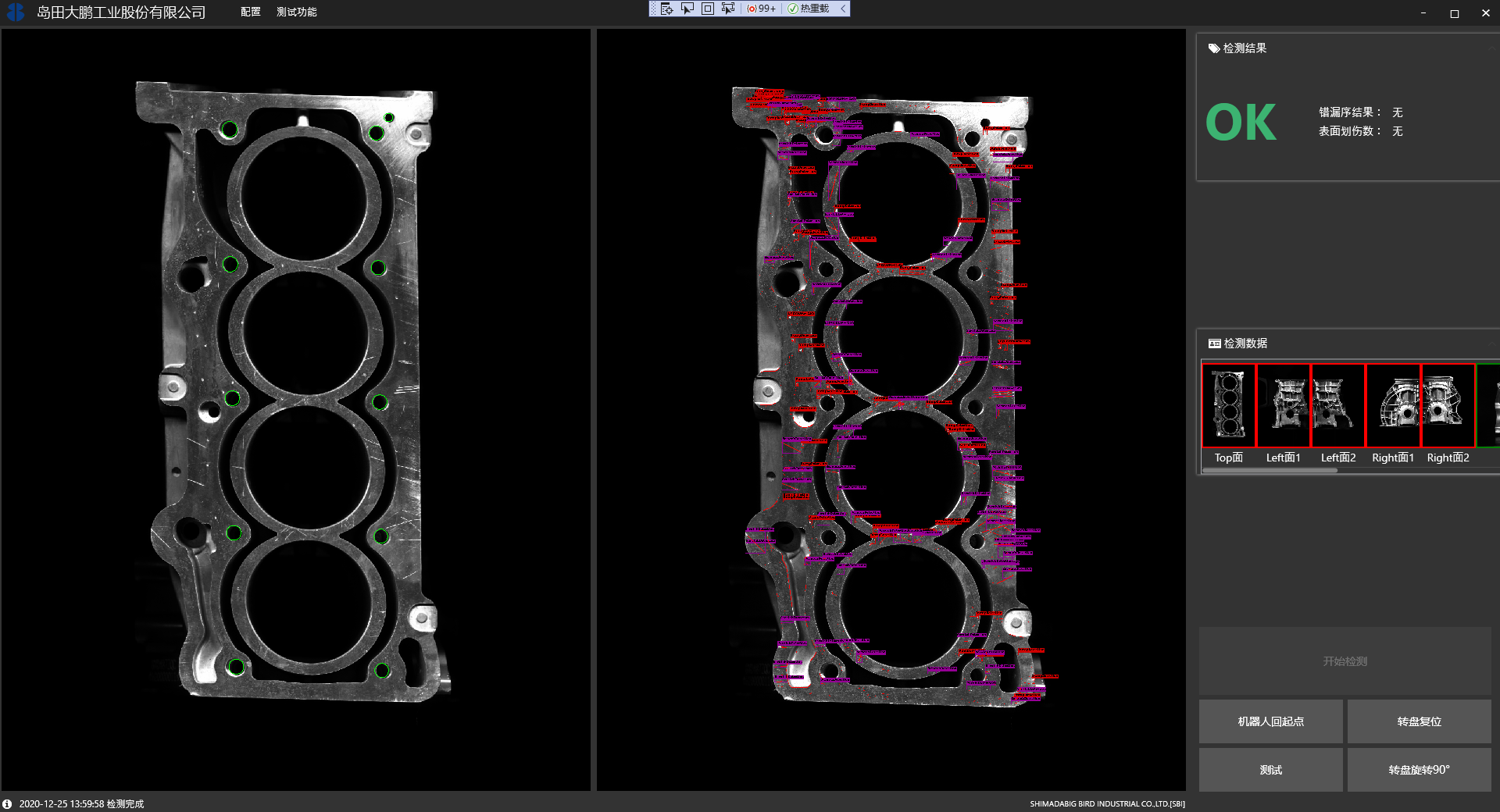

Detection process: the incoming material is photographed and identified at the entrance, and the error and leakage sequence, damage and surface iron filings of the cylinder block round holes are accurately given

Beat demand: customization

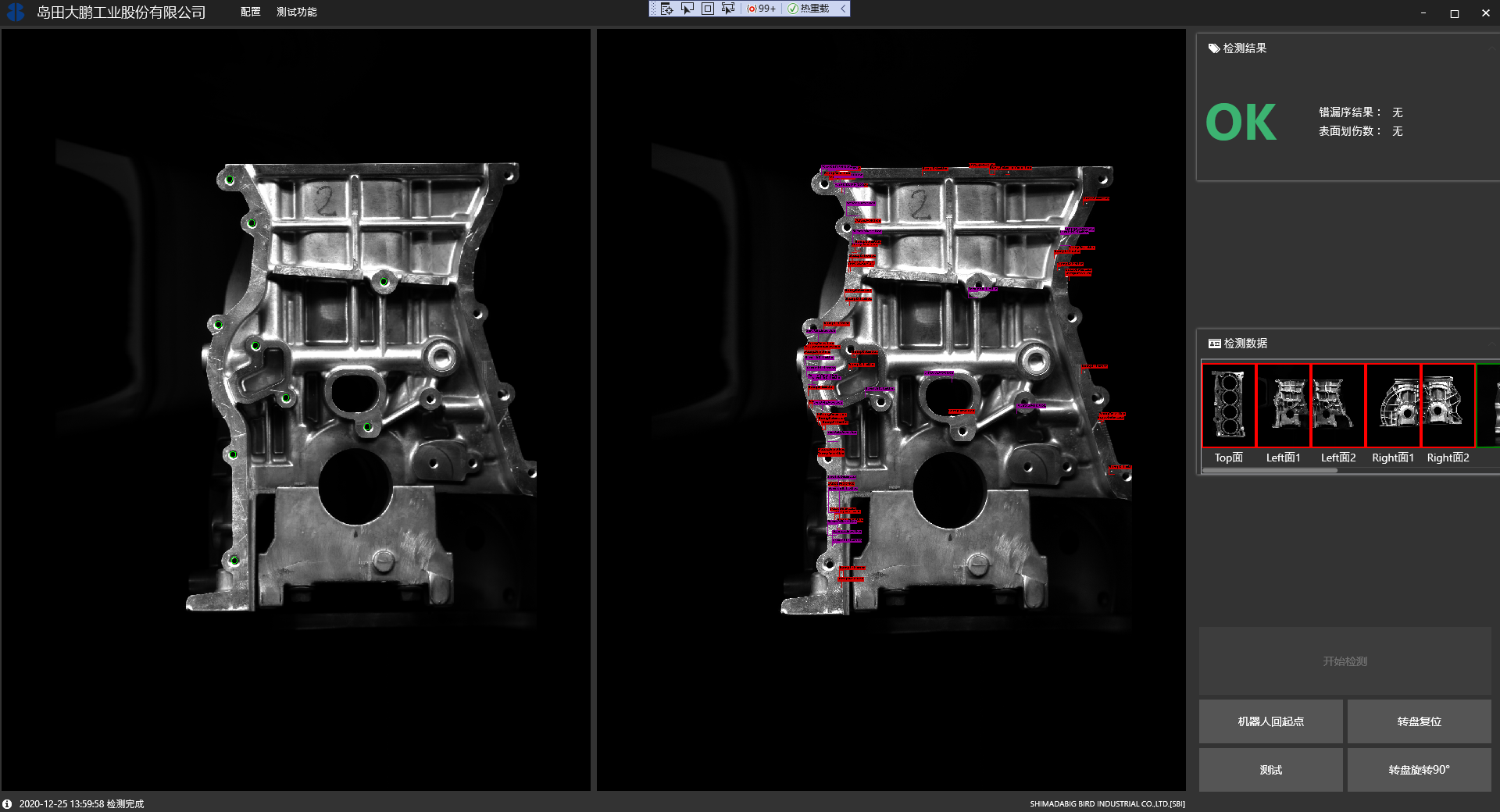

Process Description: 1. The top is equipped with a camera, a is responsible for the inspection of the upper surface of the cylinder block

2. The side is equipped with B camera, and B is responsible for the surface inspection of the cylinder block side

3. The robot carries camera a to detect the upper surface of the cylinder block

4. Turn the turntable and take photos with side camera B to detect the side surface of the cylinder block

5. Give the real-time detection results according to the photo results

Functions: 1

2. Check whether there are scratches on the machined surface of cylinder block

3. Check whether there is bump on the machining surface of cylinder block

4. Check whether there are black iron filings on the machining surface of cylinder block

5. Detect the machining surface of cylinder block through the user's drawing area

6. Real time viewing of camera images

7. Fast model switching

8. Automatic teaching of path planning